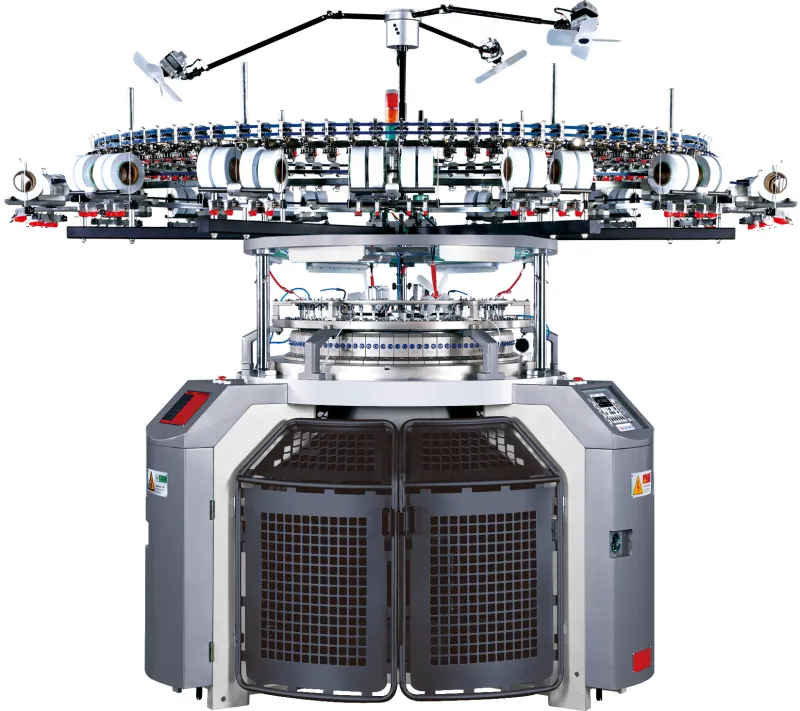

How to Choose a High-Quality Circular Knitting Machine?

Circular knitting machines are precision machines, and the coordination of each system is crucial. A weakness in any system will limit the machine's performance. This explains why, despite the seemingly simple production process, there are few truly high-quality circular knitting machines on the market.

Many customers fall into a misconception when purchasing circular knitting machines, focusing only on visible brand features such as yarn feeders and needles, while neglecting the most critical aspects of the machine itself. Sometimes, the purchased machine is like a shrimp with a crab's large claws—it looks luxurious, but the claws (money) are useless.

Therefore, today we will break down the machine from various aspects, including the support mechanism, knitting system, cleaning system, transmission mechanism, lubrication system, yarn feeding system, and tensioning mechanism, to explain what constitutes a balanced and stable machine.

The support mechanism, or frame, is like the skeleton of the human body. Just as someone with osteoporosis will have poor mobility, some machine castings are porous and loose. Such castings will significantly reduce the machine's stability. Even slight vibrations during high-speed machine operation can be transmitted to the final fabric finish. When discussing castings, natural aging is essential:

Natural aging involves placing castings outdoors, exposing them to wind, sun, rain, and seasonal temperature changes, allowing residual stress to be released, and achieving stable precision.

This process doesn't involve high technical skill, but it requires time to mature, capital tied up in inventory, and management costs. This seemingly simple process eliminates most small, unlicensed manufacturers. Many small factories produce castings as soon as they need them, sometimes even installing them on machines while they're still hot.

Meanwhile, components that haven't undergone natural aging retain residual stress. While they may be fine initially, over time, slight deformation or shrinkage can occur. This deformation is often invisible to the naked eye, but it can be fatal to precision machinery.

For example, a slight deformation (loss of flatness) in the large disc shown in the image above will cause a change in the position of the weft anchor and the take-off point of the knitting needles. This will result in inconsistent coil heights in the produced products.

Taller coils have better light transmission and appear brighter, while shorter coils have poorer light transmission and appear darker. This leads to unexplained unevenness in the knitting pattern.

Some manufacturers, in an effort to save costs, use excessively thin main coils and excessively small wickerwork, which can cause deformation after the machine has been running for a period of time.

If the same problem occurs with the main coil or the gears, it will cause changes in the gear meshing clearance.

In severe cases, this can cause the upper and lower coil needles to collide, resulting in serious damage.

The knitting system, also known as the loop-forming system, includes the core and the cylinder. The material, graduations, and precision of the fit of the core are all crucial. Today, we will mainly discuss the cylinder. The cylinder is the container for the knitting needles and is subject to repeated friction with the needles over many years. Besides ensuring lubrication, the material of the cylinder itself is critical.

A poor-quality cylinder will be worn down by the needles after a period of operation. The metal powder from the wear will mix with needle oil and be carried onto the yarn by the needles, creating oil needles. Furthermore, the position of the needles inside the worn cylinder changes, resulting in coils of inconsistent sizes and causing unresolved vertical stripes. Therefore, selecting high-quality syringes, such as those made of free-cutting alloy steel and heat-treated, is crucial. These are often overlooked by customers.

The lubrication system directly affects the lifespan of the sinker and needles, thus impacting replacement frequency and operating costs.

The sinker lubrication system must ensure adequate lubrication of the sinker shoulder, heel, and body. The location of the oil nozzle is critical. While many focus on the internal lubrication of the needle heel, the needle hook and latch are often overlooked.

An oil-air mixed spray system is essential. It mixes air and needle oil to form an atomized mixture, which is sprayed onto the needle latch and hook, ensuring the cleanliness of the needle hook and smooth closure of the needle latch. This extends the lifespan of the needles.

A good cleaning system extends cleaning time, reduces machine maintenance, minimizes downtime, and improves production efficiency.

The image shows whether the air blowing cleaning location is appropriate, covering both internal and external areas. The optim

an design is a reverse-mode, slow-motion dust removal system: the fan and syringe rotate in opposite directions, with the fan rotating slower than the syringe. This design ensures the fan remains stationary at the dust removal point for a longer and more even time, resulting in better dust removal.

Regarding the yarn feeding system, the yarn accumulator, a key focus for many, is often overlooked. Thickened square steel and a solid support frame contribute to a more stable yarn feeding system, preventing vibrations during high-speed operation and ensuring a better fabric finish.

For the transmission system, choosing reliable and stable brands for the motor and frequency converter is crucial. Synchronous belts offer a more stable transmission ratio. Bearings, though often hidden, are present in various systems and frequently overlooked by customers; it's essential to carefully inquire with the manufacturer about the bearing brands used.

In the tensioning system, besides the number of sections, speed, and the winding rollers, vibration damping is critical. A good damping system extends the lifespan of the winding machine's gearbox and reduces wear on the large disc gear.

Visit the manufacturer and inquire about the machine's installation precision, observing whether it is assembled strictly according to the required precision. This is crucial, as precision signifies the grade of materials used and the level of installation. Of course, these are only the basic requirements for a good machine.

These aspects represent the foundation of machine precision and quality. Another critical factor in choosing a manufacturer is their R&D capabilities, especially if your clients have specific requirements regarding weave and fabric.

Because, assuming machine precision is guaranteed, R&D capabilities determine the maximization of machine performance. Take a sweatshirt knitting machine as an example: the curves of the upper and lower bobbin angles, the depth of the sinker throat, and the coordination of timing, needle depth, tension, etc. How to develop the machine's overall performance (ease of fabric application, compatibility with different raw materials, yarn wrapping effect, etc.) to its strongest level is a testament to R&D capabilities.

Many people think that manufacturing circular knitting machines is simple, but we always maintain a sense of awe, believing that learning is endless. Many people think that ordinary machines have little technical content, but we believe that the more ordinary the machine model, the harder it is to make well, and the simpler the fabric, the harder it is to achieve perfection.

Because the simpler the dish, the more it tests the chef's skill.