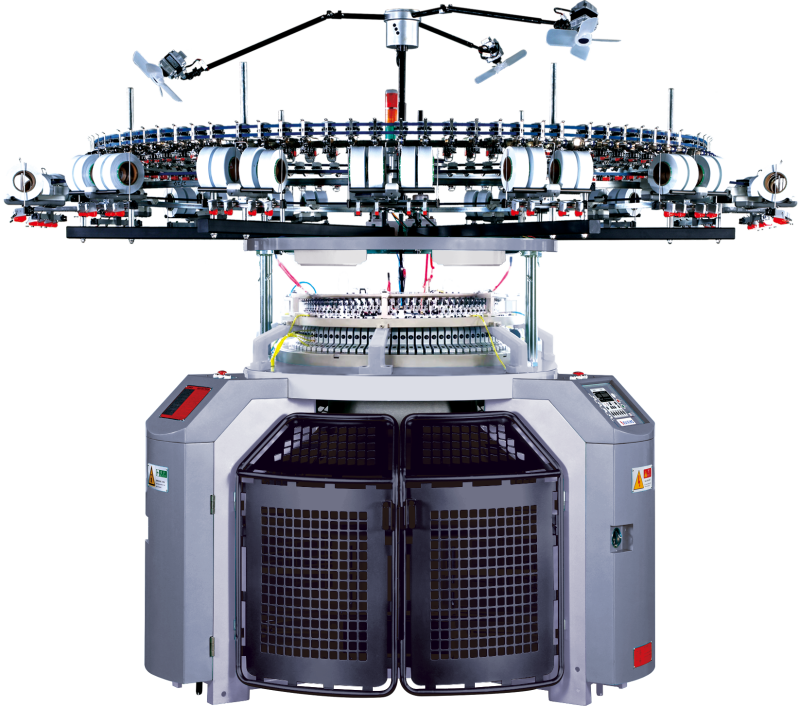

Features of Single Jersey Circular Knitting Machine

The Single Jersey Circular Knitting Machine is a widely used piece of equipment in the textile industry, particularly for knitting single-sided fabrics such as T-shirts, sportswear, and bed linens. Below are the key features of the Single Jersey Circular Knitting Machine:

1. High Production Efficiency

Fast Production: The Single Jersey Circular Knitting Machine operates at high speeds, significantly increasing production efficiency and allowing for the rapid manufacturing of large quantities of fabric. It is ideal for mass production.

Continuous Production: This machine can continuously produce a full roll of fabric without frequent changes, minimizing downtime and improving productivity.

2. Versatile Application

Single-Sided Fabrics: It is used to produce single-sided knitted fabrics, such as plain jersey, interlock, or sportswear fabric, making it ideal for manufacturing T-shirts, underwear, sportswear, and other apparel.

Adjustable Knit Structures: The machine can be adjusted to create various fabric structures, such as plain knit, ribbed knit, or terry cloth, depending on the requirements.

3. Excellent Fabric Performance

Comfort and Elasticity: Single jersey fabrics typically offer great elasticity and softness, making them ideal for making comfortable, close-fitting garments. They also have good breathability and moisture absorption, making them suitable for activewear.

Fabric Uniformity: The machine's precise control ensures even fabric thickness, reducing the chances of irregularities or defects in the fabric.

4. Simple Structure, Easy Operation

Single-Sided Knitting: The machine’s structure is relatively simple, with a single set of needles and a single set of combs, making it easy to operate and adjust. Compared to double jersey knitting machines, it is easier to handle and maintain.

High Automation: Many single jersey knitting machines are equipped with automated control systems that allow for automatic needle adjustments, speed control, and stop alarms, reducing manual effort.

5. Breathable Design

Enhanced Ventilation: Ventilation panels improve airflow, keeping you cool during intensive activities. It is designed to handle different weather conditions, ensuring comfort in both hot and cold environments.

6. Energy-Efficient and Environmentally Friendly

Low Power Consumption: Due to the high-efficiency motors and precision mechanical design, the Single Jersey Circular Knitting Machine can maintain high output while consuming relatively low energy, making it more environmentally friendly.

7. Various Fabric Pattern Design Options

Design Flexibility: The machine allows for the production of different fabric patterns by changing the needle methods or adjusting the machine settings. This includes simple plain patterns or more complex textures, enhancing the fabric's decorative appeal.

8. Stability and Durability

High Stability: High-quality single jersey knitting machines are designed for excellent stability, maintaining consistent fabric quality during long runs.

Durable: Built with precision and high-quality materials, these machines are designed to be durable and suitable for continuous operation.

9. Multiple Knitting Functions

Adjustable Needle Pitch: It can be adjusted for different needle pitches to accommodate fabrics of varying thickness and texture.

Customizable Height Settings: The machine allows for fine adjustments to meet different production needs, such as altering the feed rate or pressure to change fabric density and elasticity.

10. Easy to Operate and Maintain

Convenient Maintenance: Compared to more complex knitting machines, single jersey circular knitting machines require relatively simple maintenance, reducing machine downtime.

Efficient Needle Changing Mechanism: Many models feature a quick needle-change system, allowing operators to easily switch to different needle types for various production requirements, saving time.

11. Cost-Effective

High Cost-Performance: Single jersey circular knitting machines are relatively affordable compared to other types of knitting machines. Their high-speed production also helps reduce overall production costs, making them an excellent choice for textile manufacturers.

The Single Jersey Circular Knitting Machine, with its high efficiency, stability, ease of operation, energy savings, and versatility, is one of the most widely used machines in the textile industry. It is ideal for large-scale production of comfortable, high-quality single-knit fabrics. If you're looking to produce high-volume, top-quality single jersey fabric, this machine is a perfect choice for your business.